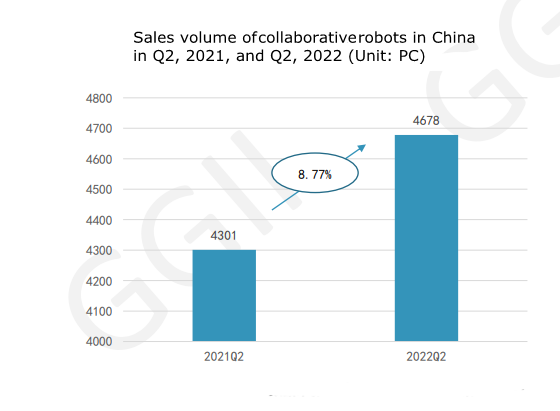

Since China's industrial robot market suffered a "cold wave" in 2019, collaborative robots have attracted great attention from the capital market by virtue of the strength of the counter-trend, especially since the total shipment of 2022H1 continued to grow year-on-year. According to the data of GGII, the sales volume of industrial robots in the 2022 H1 Chinese market increased by 3.78% year on year, with collaborative robots and six-axis robots with medium and large loads leading the way.

In 2022Q2, AUBO Robotics leads the domestic market in the total sales volume of collaborative robots in the Chinese market.

According to GGII data, the total sales volume of collaborative robots in the Chinese market in 2022Q2 was 4678pcs, up 8.77% year on year; Among them, 3959pcs are domestic, accounting for 85.54%; 669pcs from foreign-funded companies, accounting for 14.46%.

Although the rapid development of cooperative robots is largely driven by the stimulus of a large number of explicit demands in the industrial market, when sorting out the history of collaborative robots, GGII was surprised to find that the birth of collaborative robots came from accidental project research.

The bud of collaborative robots originated from a research project funded by the European Union in 2005, which was jointly studied by ABB, Kuka, and other industrial robot giants and robot industry chain enterprises. At that time, the original intention of the research was to create a small and smart robot that could be affordable for SMEs to cope with the trend of the manufacturing industry moving out of the EU to low-labor-cost countries.

However, due to objective factors such as technology, cognition, and cost demand, collaborative robots performed mediocrely in the industrial robot market at that time and did not meet the ideal expectations. It was not until 2016 that the global sales of collaborative robots began to show explosive growth. At that time, the global sales of collaborative robots exceeded 10,000 units, with a year-on-year growth of more than 90%.

However, the development of domestic collaborative robots began in 2013. With the entry of foreign manufacturers UR and Rethink into the Chinese market, collaborative robots rose in China, and then a group of domestic collaborative robot manufacturers represented by AUBO Robotics emerged to actively lay out the cooperative robot market. In 2016, the International Organization for Standardization issued the latest industrial standard for collaborative robots, which put collaborative robots on the right track to the road of standardized production and opened the first year of the development of collaborative robots.

After 2016, the development of domestic collaborative robots also began to enter the fast lane, and the annual sales volume achieved steady growth. GGII data shows that in 2016, the sales volume of collaborative robots in China was 2300pcs, with a market scale of 360 million Yuan. In 2021, the sales volume of collaborative robots in China was 18600pcs, with a year-on-year growth of 87.62%. Domestic collaborative robot manufacturers have also become the leading force in the Chinese market, with a market share of nearly 70%.

Among them, the collaborative robot enterprises represented by AUBO Robotics successfully broke the market monopoly of foreign brands by continuously strengthening product and application innovation. AUBO Robotics has made outstanding achievements in the fields of automobile, 3C, semiconductors, mechanical equipment, health, patrol inspection, new retail, logistics, education, etc.

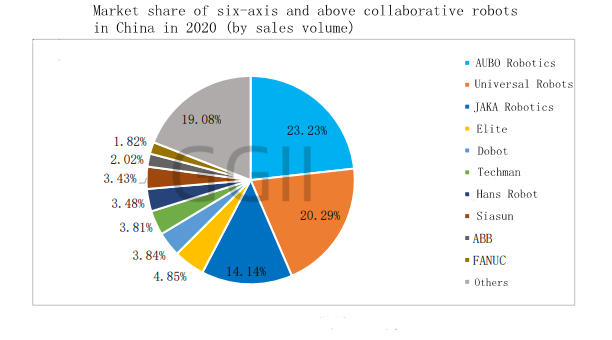

In 2020, with its focus on industrial and nonindustrial markets, AUBO Robotics achieved rapid growth in its sales volume. According to the data of the Blue Book on the Development of Collaborative Robot Industry in 2021 jointly released by GGII, in 2020, AUBO Robotics surpassed UR to top the domestic collaborative robot sales list, and UR fell to second place. In addition, AUBO Robotics data showed that in 2021, its production and sales volume increased by 100%, with sales revenue of nearly 400 million Yuan, and it has a leading edge in the domestic market.

The development of AUBO Robotics is just like a "perpetual motion machine". It has tirelessly gone from pioneering in the industrial subdivision field to batch application, and from continuous attempts in a commercial application to multi-point flowering. It has stepped out of the innovation path of the collaborative robot industry, successfully created many "No. 1" records in China, and has also become the "pioneer" of the industry.

(1) Industrial applications

Taking the industrial field as an example, in 2017, AUBO Robotics successfully built the first insulated cup production line in the hardware industry and became the first collaborative robot enterprise with 3C industry-scale application in China. At the same time, it built the first collaborative robot flexible assembly line for automotive industry lights in China and became the first domestic collaborative robot enterprise to enter Huawei, BMW, and other leading enterprises the next year.

In the traditional glue coating process, it is difficult to match the glue output amount control with the running speed of the robot. At the same time, due to the changes in the workpiece curve and surface, the robot's large posture changes will lead to inconsistent glue output. In addition, the smooth transition between different tracks and the inertial force of the glue gun during dispensing will lead to deviation of the glue coating track.

Advantages of AUBO Robotics glue application technology:

1. The unique system function of the AUBO robot can realize smooth transition at the corner of the track and ensure the consistency of glue dispensing;

2. In addition, it can realize the self-adaptive matching between the glue output amount of the glue gun and the running speed of the robot to ensure the uniformity of glue output;

3. The programming instruction design has its own group instruction function designed for the gluing industry to ensure the continuity of the trajectory;

4. In addition, with the introduction of 2D/3D vision technology, offline simulation software, and the development of modern control methods, it can also achieve a high degree of integration of quality detection, tracking, and other functions in the entire gluing process, and achieve intelligent operation of the gluing system. In addition to being used in the automobile industry, it can also be widely used in automobile parts, hardware and household appliances, 3C electronics, and other industries.

In 2019, AUBO Robotics developed the first collaborative robot for welding. In the same year, the inspection robot created together with the cooperative partners was successfully applied in the field of electric power inspection on a large scale, and the world's first flexible assembly line for white household appliances was created. So far, AUBO Robotics' pioneering journey in the field of industrial subdivision has been pushed to a small climax.

The AUBO-i series collaborative robot has developed a professional welding process package, which can complete the welding methods of pulse welding and DC welding. The program can be saved and reused, realizing multi-welding processes of laser welding, gas-shielded welding, etc. Instead of manual welding, high-strength and repetitive welding operations are carried out. Compared with manual welding, the welding line quality is more stable and the shape is more beautiful.

AUBO Robotics welding application technology advantages:

1. The AUBO Robotics welding process package perfectly matches the process requirements of arc starting, arc stopping, swing welding, etc., making the welding line quality more stable and forming more beautiful;

2. The welding power, welding speed, and wire feeding speed can be adjusted independently through the welding process package. Eliminate welding gun blockage, reduce high consumption and long time-consuming manual operation process;

3. It supports a variety of communication protocols and is perfectly compatible with mainstream welding brands such as Megmeet, Panasonic, and Rick.

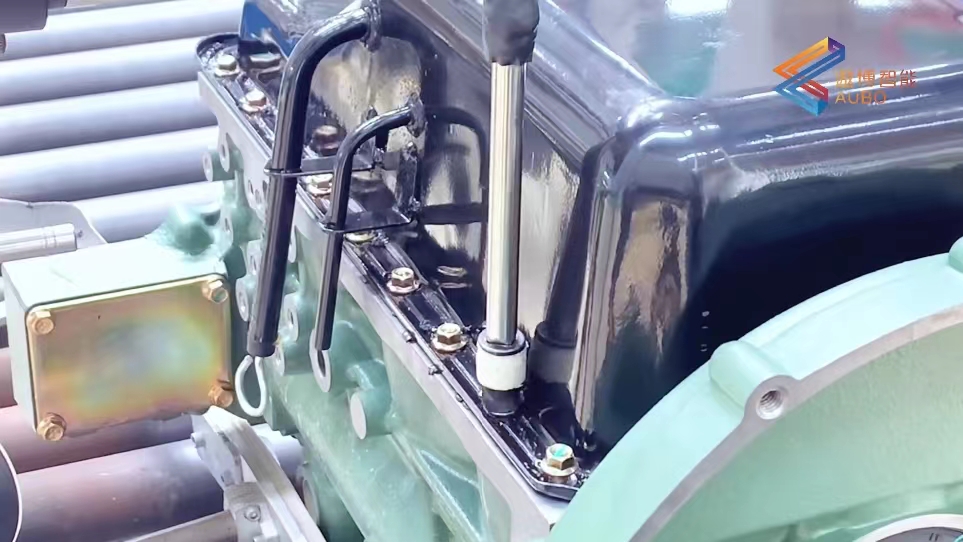

In order to ensure assembly quality, the requirements for tightening state and torque accuracy control in the production process are also getting higher and higher. The defects such as tightening missing and insufficient torque caused by existing manual operations can not meet the production requirements. AUBO robot supports level 10 collision detection and sensor safety detection, which is safe and reliable, without protection, and can work side by side with people. The use of an AUBO robot to replace manual work for bolt tightening not only solves the problems of manual missed tightening and personnel flow, but also ensures the consistency of the product and improves the production quality of the engine.

AUBO Robotics screw lock application technology advantages:

1. The system is open and supports the original Profinet communication. Most of the other domestic brands achieve this through the conversion of boards and cards. The communication efficiency is low and the delay is high. AUBO Robotics' original Profinet communication is stable, and it can directly connect with the MES system of large and medium-sized automobile factories and automobile parts manufacturers' workshops;

2. In terms of communication mode, it matches the mainstream tightening gun in the market, such as Atlas, Bosch, Deprag, etc;

3. AUBO I series collaborative robots can adapt to 60NM torque screw locking applications at most. Through camera vision and other coordination methods, screw locking can be realized by taking pictures and positioning.

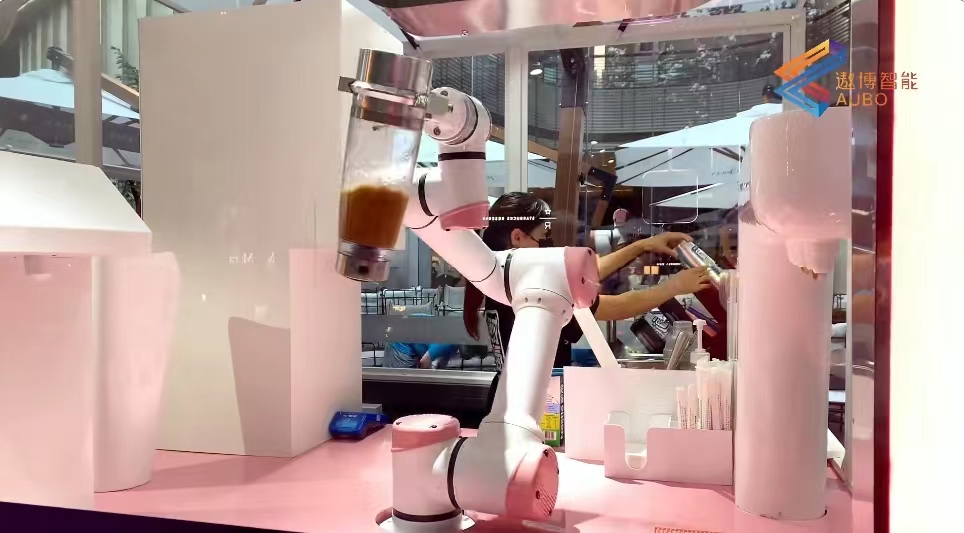

(2) Commercial applications

The year 2020 was a key year for the development of AUBO Robotics. This year, AUBO Robotics not only built the first collaborative robot intelligent flexible production line for collaborative robot production in China, the first collaborative robot restaurant for mass production in the world but also became the first enterprise to achieve mass production of intelligent physiotherapy robots. As a result, AUBO Robotics opened a pioneering moment for the large-scale application of collaborative robots in the commercial field.

From desserts/drinks/alcohol workstations to smart kitchens and smart restaurants, AUBO Robotics' penetration in the commercial field has blossomed in many ways and continues to expand the application boundary of collaborative robots in the commercial field.

Since 2021, AUBO Robotics and its partners have also handed over outstanding achievements such as "the first explosion-proof robot in the world was released and applied in batches", "large-scale application in outdoor construction robots", "the only domestic cooperative robot that is standardized to be applied to built-in composite machine tools", and "the first domestic six-axis cooperative robot that meets the certification requirements of three types of medical devices". In addition, AUBO Robotics' application exploration in agriculture, architecture, and other sectors is also continuing.

Taking agricultural fruit and vegetable picking as an example, aiming at the problems of strong seasonality, low efficiency, and labor shortage in traditional manual picking operations, the fruit, and vegetable picking robot created by AUBO Robotics and its partners came into being. Through the cooperation of the walking system, visual system, and picking execution system, it can pick fruit in an average of 8-10 seconds, with a success rate of more than 90%, and the speed and efficiency are better than humans. At present, the AUBO Robotics' fruit and vegetable picking robot has been applied in large quantities in Suzhou Xiangcheng Caoyang Ecological Agricultural Park, Changshu National Agricultural Science and Technology Park, Beijing Hongfu Agricultural Base, etc.

(3) Application in the medical and health field

In September 2020, AUBO Robotics joined hands with Xiuyu, a domestic chain giant in the field of health, to launch the world's first intelligent physiotherapy robot at the Shanghai International Industrial Expo and promote large-scale applications. At the beginning of 2022, AOBO and Xiuyu signed a purchase agreement for 10,000pcs physiotherapy robots, which will be delivered in the next three years. This is also the largest single order in the history of the collaborative robot industry.

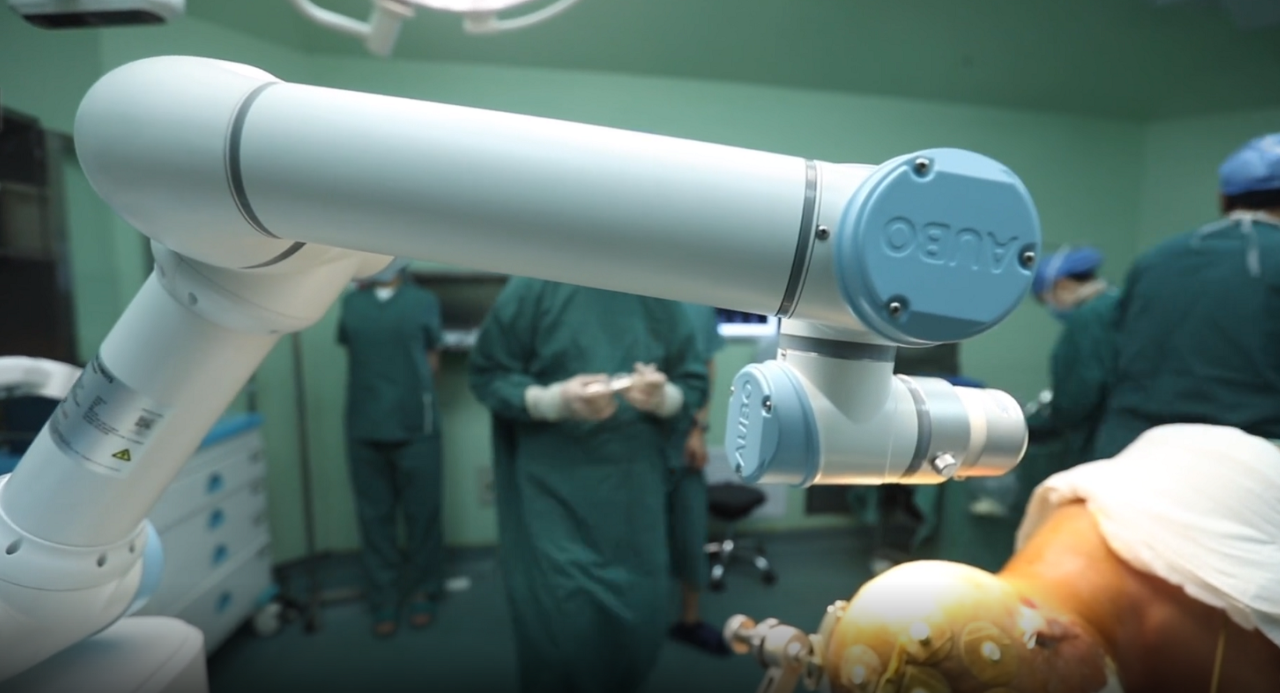

Apart from the application scenarios in the field of general health, AUBO Robotics also has outstanding performance in other aspects of the medical field. For example, in 2022, the first intracerebral hemorrhage operation carried out by China-origin surgical robot was successfully implemented, and one of the "leading roles" was AUBO Robot.

The surgical robot created by AUBO Robotics partners, while inheriting the platform technology and clinical advantages of existing specifications, emphasizes the automation, ease of use, and standardization of products. The complex operation is preset as an intelligent standard module, so the whole machine is flexible, the automatic registration of the mechanical arm is easy to use, and the positioning accuracy error reaches the sub-millimeter level. In the future, it can expand the clinical coverage of biopsy, provide an excellent personalized surgical program, assist doctors to complete various types of cerebral hemorrhage, brain biopsy, craniotomy navigation, and related minimally invasive brain surgery, make it safer, easier to use and more efficient, realize the localization of core components, and effectively reduce costs.

In addition, as the first domestic six-axis collaborative robot enterprise meeting the certification requirements of three types of medical devices, AUBO Robotics' products are widely used in neurosurgery, orthopedics, blood station testing, and other fields.

At the same time, in order to further promote the standardization and standardized R&D and production of the industry, AUBO Robotics has also made great contributions to the formulation of collaborative robot standards. It has successively participated in the formulation of 21pcs national standards and industrial standards for robots, and has taken the lead in formulating 3pcs national standards.

The reason why AUBO Robotics can take the lead by virtue of its products is also due to its "paranoia" in product research and development and quality. In addition to ISO 13849 PL=d certification, EU CE, North America NRTL, China CR, Korea KCs, SEMI S2, cleanliness class 5, and other certifications, AUBO Robotics and its partners was the first in the industry to promote explosion-proof collaborative robots in 2021, opening up another new application field of collaborative robot in the industrial market. It is the first enterprise in the collaborative robot industry to obtain the IECEx (Explosion-proof Electrical Product Certification System) and CNAS explosion-proof certification, marking that the collaborative robot has officially entered the practical application of chemical, petroleum and other high-risk scenarios. Since then, "safe and reliable" has become the unique label of AUBO Robotics.

If we say that the "paranoia" of products is an important weight for AUBO Robotics to success in the short term, then its perseverance in "education" and "talents", or even its deep cultivation of spare no effort, is the key point for AUBO Robotics to win in the future. The extreme emphasis on education and talent is closely related to Mr. Wei Hongxing, the founder of AUBO Robotics. As a scholar entrepreneur, Mr. Wei Hongxing attaches great importance to the introduction and training of talents.

In the field of education, AUBO Robotics has established a professional institution with the brand "AUBO College". The college has carried out in-depth integration of industry and education and school-enterprise cooperation with many domestic universities in the fields of talent training, curriculum system, teacher training, student internship and training, competition and employment, training base construction, and co-construction of industrial colleges.

At the same time, the "1+X" professional skill level certificate developed by AUBO Robotics for the Ministry of Education is the first national professional skill level standard in the field of intelligent robots in China. The standard aims to cultivate compound talents who adapt to the latest development of the intelligent manufacturing industry and master the technical skills of collaborative robots, filling the gap in the domestic professional skill level standard of cooperative robots. At the same time, it provides an implementable basis for college teaching, training, and evaluation promotion of enterprise's on-the-job employees, and has a very important role and significance for enterprises to move towards the road of intelligent manufacturing development.

In 2021, AUBO Robotics, together with Taylor & Francis International Publishing Group, jointly created Cobot (ISSN 2752-5813), the world's first international journal in the field of collaborative robot technology, to provide a platform for practitioners of global collaborative robots (robots) to publish and disseminate research results, ideas, and knowledge. In order to ensure the professionalism and authority of the journal, Cobot invited Mr. Ni Guangnan, and Mr. Wang Yaonan, academicians of the Chinese Academy of Engineering, and other authoritative experts in the industry to serve as consultants of the journal committee.

In terms of products, AUBO Robotics has also launched several product series, such as i-series collaborative robots (industrial), E-series collaborative robots (educational), C-series collaborative robots (commercial), and Heiner series mobile collaborative robots.

At present, the Chinese collborative robot market is still in its infancy, and there is still enough room for growth and trial and error opportunities in terms of scale and product extension. The "pan" positioning of AUBO Robotics' products is also based on the continuous exploration of more application scenarios.

As a guest of CCTV's "Journey of Discovery - Future Mission", Mr. Wei Hongxing once said that the development of cooperative robots needs to constantly break through the boundaries of technology, deeply integrate with the application scenarios of all walks of life, stimulate new momentum and create new opportunities. For AUBO Robotics, "intelligence changes the world and collaboration makes the future" is not a slogan, but a real enterprise mission. By replacing repetitive work with collaborative robots, industry and commerce can enjoy the new development dividends brought by "intelligence", which is the future that AUBO Robotics hopes for and the internal driving force that it is exploring and practicing.

The pioneering journey of AUBO Robotics' industrial applications continues. No one can give a concrete answer to the direction and field of future collaborative robots. But we have reason to believe that, driven by technology, AUBO Robotics will be able to give a perfect answer to the market and users.