Products:

J1: LHSG-25-100-C-III-SXTB J2: LHSG-25-100-C-III-SXTB J3: LHSG-25-100-C-III-SXTB

J4: LHSG-14-100-C-III-SXTB J5: LHSG-14-100-C-III-SXTB J6: LHSG-14-100-C-III-SXTB

Advantages:

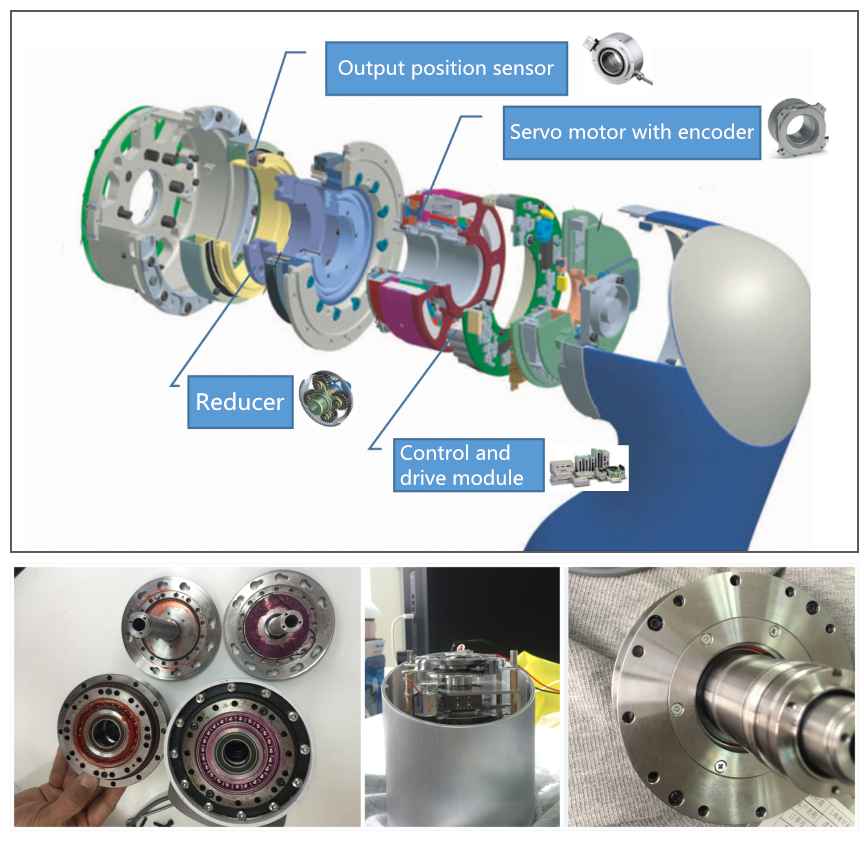

Collaborative robots have extremely high requirements for integration and have high requirements for high-speed and low-speed axis machining. The integrated design structure integrates the high-speed shaft and the wave generator cam, which effectively controls the runout of the input end.

Besides, our company has added a non-contact bearing at the input end, which effectively reduces the starting torque while ensuring no oil leakage.

At present, this structure is used by mainstream domestic robot manufacturers. Under the condition of controlling the cost, the structure is simplified, the matching of parts is reduced, and the stability of the structure is enhanced.

Attention:

The coaxiality of the matching flange, the flatness is 0.01, the high-speed shaft runout is within the range of 0.05, and the low-speed axis is generally within the range of 0.1.