The LHSG high-torque hollow-shaft flexspline strain wave gear can be widely used in: robots, humanoid robots, metal processing machinery, semiconductor manufacturing equipment, laser equipment, printed circuit manufacturing equipment, telescopes, metal machine tools, photovoltaic equipment, and other fields.

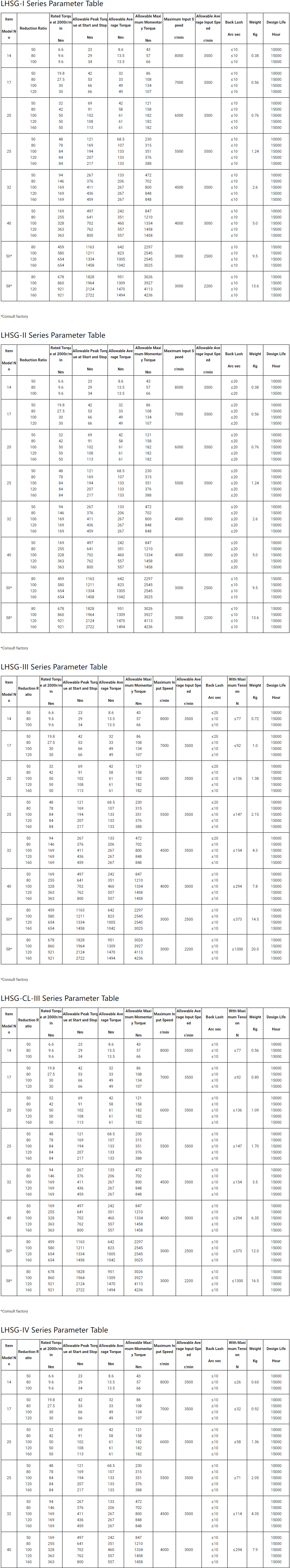

The LHSG high-torque hollow-shaft flexspline strain wave gear series is divided into six models according to the connection form of the input end and the wave generator cam and other aspects:

LHSG-I model: The input shaft is directly matched with the wave generator's inner hole and connected by a flat key. It can be used to connect the circular spline input and flexspline end output and vice versa.

LHSG-II model: The input shaft is connected to the wave generator's inner hole through a cross slider coupling. It can be used to connect the circular spline input and flexspline end output and vice versa.

LHSG-III model: There is a large-diameter hollow shaft hole in the middle of the wave generator cam, and a support bearing is designed inside the strain wave gear. It is very suitable for threading. The fully sealed structure is easy to install.

LHSG-III-ST model: Based on the LHSG-III strain wave gear, the original fully enclosed structure is simplified to a semi-enclosed structure, allowing users to have greater design freedom.

LHSG-CL-III model: It is a lightweight version of the LHSG-III. Through the optimization of structure and materials, the original performance parameters remain unchanged. The strain wave gear's weight is reduced to withstand faster speeds and larger loads after being used on industrial robots.

LHSG-IV model: The wave generator cam comes with an input shaft, and the strain wave gear is designed with a supporting bearing inside and a fully sealed structure. It is very suitable for occasions where bevel gears or timing belt transmissions need to be installed at the input end.